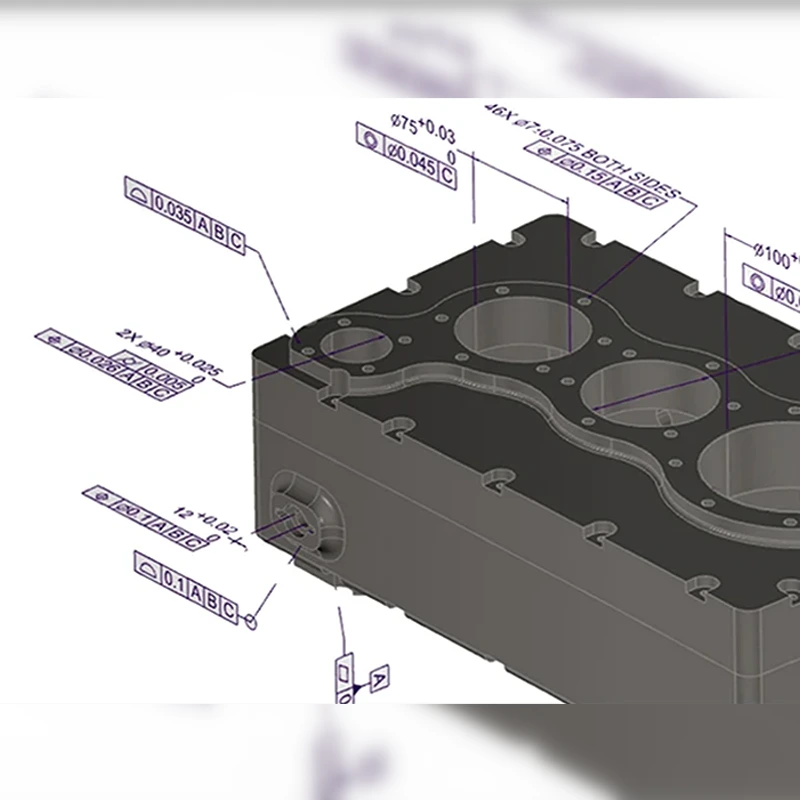

🔹We are approved for Digital Product Definition (DPD) and Model-Based Definition (MBD) requirements for Boeing projects. Our team works directly with the latest CATIA MBD models and PMI annotations for:

- Model interpretation with embedded tolerances & manufacturing info

- Digital workflow integration for toolpath, inspection & FAI

- Audit-ready documentation for aerospace compliance

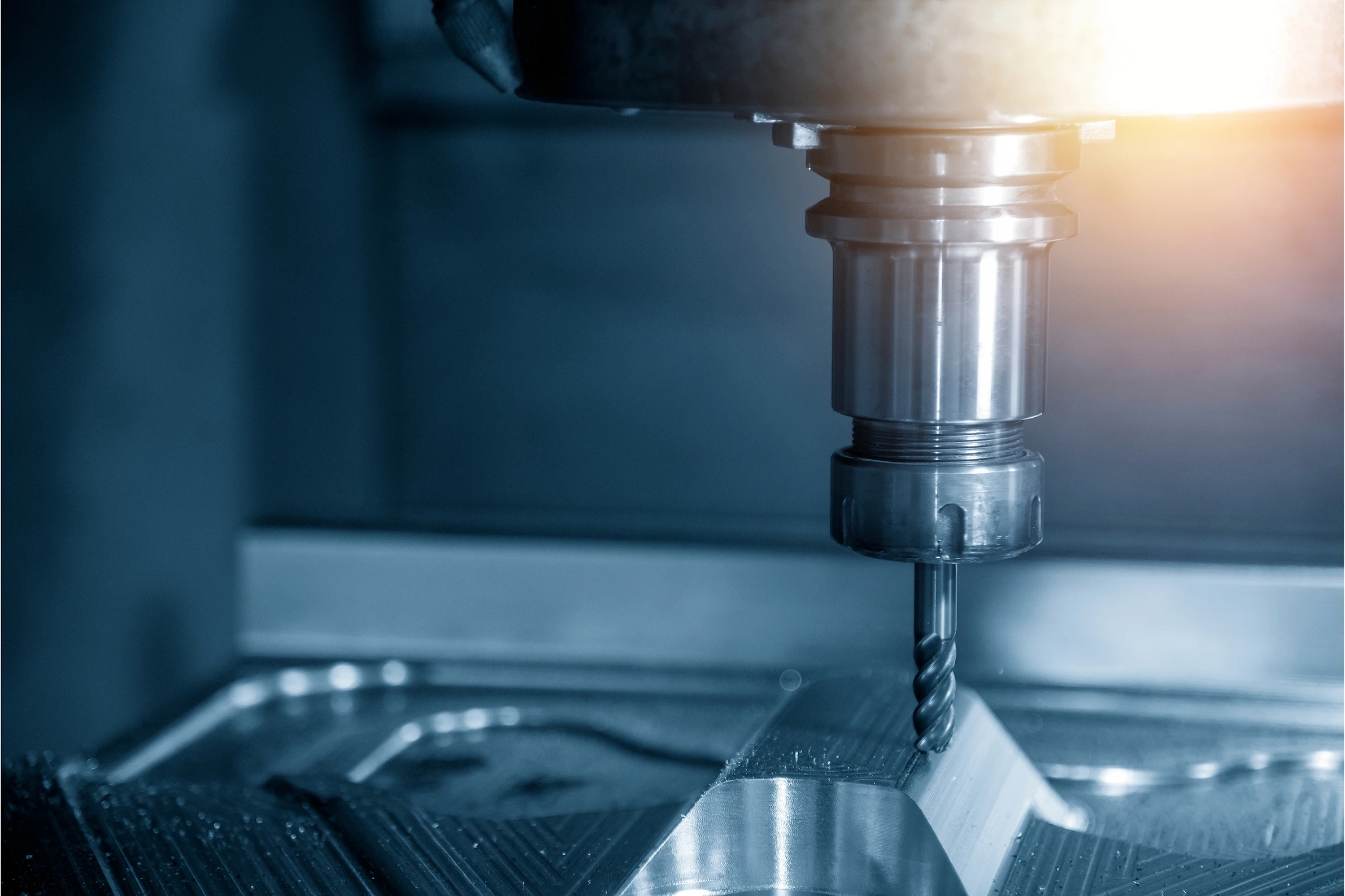

Advanced CAD/CAM Software for Aerospace Component Manufacturing

🔹Our engineering software suite includes:

- Fusion 360 CAD – Design, simulation, tooling, and fixture development

- PowerMill CAM – High-precision NC programming for 3-, 4-, and 5-axis machining

- CATIA – Aligning with native CAT models and Airbus/Boeing ecosystems